In Tech Note “Selection of Optical Connectors”, we discuss the reasons for the common use of three popular connectors: ST, FC and SC. Because the focus of the discussion was on the use and misuse of Standards in connector selection, we didn’t go into much technical detail on how connectors actually work. This Note’s focus is on selection of the TYPE of connector.

What are the basic limitations of connectors? Almost all commonly used connectors are of the ferrule type in which each fiber is located on the axis of a plug and the two fibers are aligned by means of a so-called alignment sleeve which forms the heart of the through adapter. It is pretty obvious that the fibers in each plug should have their axes lined up as perfectly as possible. A misalignment of, say, 5 um would lead to very high losses with singlemode fiber (about 3 to 4dB) but would cause a fairly minor loss in typical 62.5/125um multimode fibers (0.2 to 0.8dB, depending on measurement conditions). Another possible issue is angular misalignment of the fiber cores and yet another is separation between the ends of the fibers. Rather amazingly, the quality of modern fibers and the precision of connector manufacture is such that it is uncommon to see losses much greater than 0.5 to 1.0dB with either singlemode or multimode fibers. In fact, it is quite common to measure losses below 0.1dB.

This last number is actually very revealing about the way the connector operates. To step back into the mists of time (ie 1970s and 1980s), a major concern back then was the possibility that the end faces of the fibers in the two plugs would contact each other as it was thought that this could potentially lead to scratching of the fiber and consequent deterioration of the joint loss. As a result, connectors were designed to have a very narrowly specified gap between the two end faces. However, a problem with these connectors is that of Fresnel loss which can add 0.34dB to the other connector loss factors. Fresnel loss is actually due to the reflection that occurs when light travels between two mediums with different refractive indices. Your reflection when you look out of a glass window is just this and it amounts to about 4% of the light being reflected at each of the two interfaces: that’s a total of 8% Fresnel reflection. Another way of looking at this is that there is an 8% loss of light passing through the window which is equivalent to about a 0.34dB loss. Exactly the same occurs in a connector where there is a small gap between the fiber end faces so that such an end gap connector cannot possibly have a loss less than 0.34dB. This is equivalent to a return loss of about 12dB.

Singlemode connectors such as the FC and the many developments since then have all relied on keying the connector ferrule so that there is no possibility of the end faces rotating with respect to each other. Such designs enable the ferrules to be springloaded so that the end faces are actually forced against each other under some slight pressure. If the gap between the core regions of the fibers is less than about a quarter of the wavelength of the light passing through the joint (ie 0.3um or less) the Fresnel reflections are dramatically reduced to the point where the Fresnel loss mechanism is essentially eliminated.

Which is nice because our link budget has suddenly improved by a third of a dB at each through adapter.

However, the real benefit, particularly for high speed digital or high linearity analog systems, is in the reduction of the reflections back from connectors in the system to the laser that actually drives the system. A typical such Physical Contact (PC) connector will have a return loss of better than 25dB: much higher than the 12dB of the original basic connector. While it is easy and useful for many purposes to visualize the light traversing an optical fiber as some sort of fluid which is emitted by a device such as a laser or an LED the reality is that it is an electromagnetic wave which is ultimately subject to the same constraints that apply to other EM waves such as radio waves. Those of you with experience in radio engineering know that issues such as VSWR (particularly in transmitters) and transmission path reflections can play a critical role in the operation or otherwise of RF systems. There is no reason to suspect that optical transmission should be any different and indeed it is not………. Subject to a few caveats.

The most important caveat is that many optical transmitting devices are not very pure sources. For example, LEDs are very non coherent which means that the light they emit has completely random phases and covers a broad spectrum which can be as much as 100nm for a 1310nm device. However, Fabry Perot lasers (FP) are a lot more pure with spectral widths down to 2 or 3 nm and Distributed Feedback lasers (DFB) are even more so being as low as 0.03nm. Another key issue here is that lasers are optical amplifiers which generate light by means of some internal optical feedback mechanism whereas LEDs are spontaneous emitters without the amplification element. So what happens when an optical amplifier has some light injected into it? If the injected light is coherent with what’s going on within the lasing cavity, that light may be amplified but the chances are that that amplified light will not be in phase with the existing light so there will be constructive and destructive interference to some degree. Consequently, those Fresnel reflections mentioned above suddenly take on major importance because much of their energy will sneak back into the laser’s active region and effectively cause optical noise.

The importance and level of such noise will depend on the application so that an FP laser based 100Mbps Ethernet system will operate quite happily when standard PC connectors are used but a DFB laser based 10Gbps system would most likely not work at all or have very erratic performance. The situation becomes even more dire with analog systems such as CATV over fiber or RF over fiber systems which are extremely sensitive to reflection induced noise.

What to do?

Like most engineering problems there are a number of techniques that can be used by themselves or in tandem. Firstly, it is often good practice to use lasers with built in optical isolators. These are devices that act as optical diodes and dramatically reduce the amount of reflections that can get back into the laser. Because of their extreme sensitivity to reflections most DFB lasers used in communications systems are sold with at least one built in isolator.

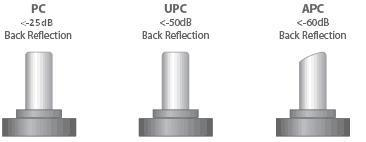

Secondly, the reflections can be reduced by using either Ultra Physical Contact (UPC) connectors or Angled Physical Contact (APC) connectors as shown in Figure 1. The UPC reduces reflections (ie increases return loss) by extremely fine polishing of the ends of the fibers so that the return loss can be extended from the 30dB typical of PC connectors to greater than 50dB. A problem with the UPC is that very slight contamination can cause major variations in return loss. The APC connector is altogether much more crafty: instead of a contact end face which is perpendicular to the fiber axis the end face is manufactured so that it is at an angle of 8º to the axis. Any reflection light bounces back from the interface at 16º to the axis which is greater than can be constrained by the fiber core/cladding interface so is thus lost. Consequently, return losses of greater than 60dB are easily achieved by APC connectors which are available in most major types such as ST, FC, SC and LC. Note that contamination can also degrade the performance of APC connectors but to nowhere near the degree experienced by the UPC.

Thirdly, it is possible to use an external optical isolator or even an optical circulator at the transmitter end in an attempt to prevent reflections getting back into the laser. This can help but is not as effective as avoiding reflections in the first place by using APC connectors.

So we get back to the original issue: what type of connector should be used?

The answer, as always, is “it depends”. For conventional digital systems operating at rates up to 1Gbps or so the PC connector is generally fine with little or no problems provided the return loss is greater than 20 to 25dB. The APC type is recommended for higher speed systems, although UPC types are also sometimes used.

For amplitude modulated analog systems such as CATV, RF on fiber and even RGB links the APC is strongly recommended as an extremely reliable way of achieving the high return losses essential in such systems.

DO NOT attempt to use conventional PC type connectors in such systems because it just leads to a world of pain.

OSD has over the years come across several such situations and in all cases the key problem for the end user is marginal performance when things are going OK interspersed with apparently random interruptions to the service when nothing seems to work. The long term fix is to replace ALL the connectors in the optical path between transmitter and receiver with APC types but a (very) short term fix is to use index matching gel at each connector junction. Such gels can be well matched to the refractive index of the singlemode fiber’s core so that the return loss is improved to above 50dB which is often enough to get the system out of trouble. Unfortunately, it is likely in most systems that ongoing fiber rearrangements and general cable work will see new PC connector connections made without any gell and the systems will once again become unreliable.

Finally, do remember that it is essential to connect PC plugs to PC plugs and APC plugs to APC plugs. Connecting PC to APC results in several dB loss through the joint and a return loss down around 14dB: the worst of both worlds!

Please contact OSD’s system engineers for further information and advice on connector issues.